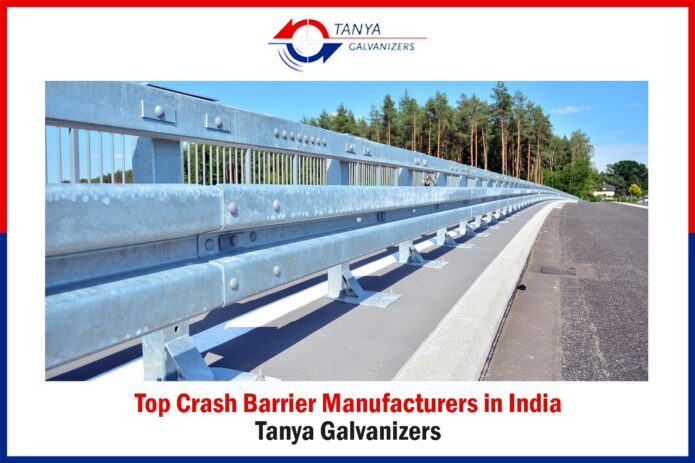

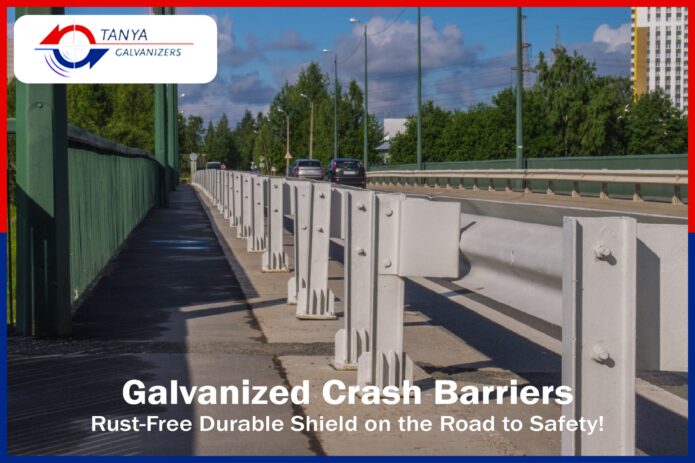

When it comes to road safety, crash barriers play a crucial role. These protective structures are more than just roadside installations; they are lifesaving shields that absorb impact and prevent vehicles from veering off the path. That’s why choosing the right crash barrier manufacturers is critical for highways, bridges, and high-risk zones.

This blog helps you understand how crash barriers work, why galvanizing matters, and what to consider when selecting a manufacturer. We’ll also introduce Tanya Galvanizers, one of India’s most reliable crash barrier galvanizing service providers.

What Are Crash Barriers and Why Are They Important?

Crash barriers, often called guardrails or safety barriers, are installed along roads, highways, and bridges to:

- Prevent vehicles from entering oncoming traffic

- Minimize the severity of accidents

- Absorb impact energy

- Protect pedestrians, infrastructure, and structures

Without well-manufactured barriers, the risk of fatal road accidents increases drastically. Hence, choosing certified crash barrier manufacturers becomes a matter of public safety.

Types of Crash Barriers

Crash barriers come in various types depending on the use case and location:

- W-Beam Crash Barrier

- Widely used

- Suitable for highways and flyovers

- Thrie-Beam Crash Barrier

- Offers higher strength and wider coverage

- Ideal for hilly and sharp-curved terrains

- Bridge Crash Barriers

- Used to safeguard the edges of bridges and overpasses

- Protects from falls into rivers, railways, or deep valleys

- Median Barriers

- Prevent head-on collisions by stopping vehicles from crossing medians

- Flexible and Rigid Barriers

- Chosen based on environment, impact risk, and design needs

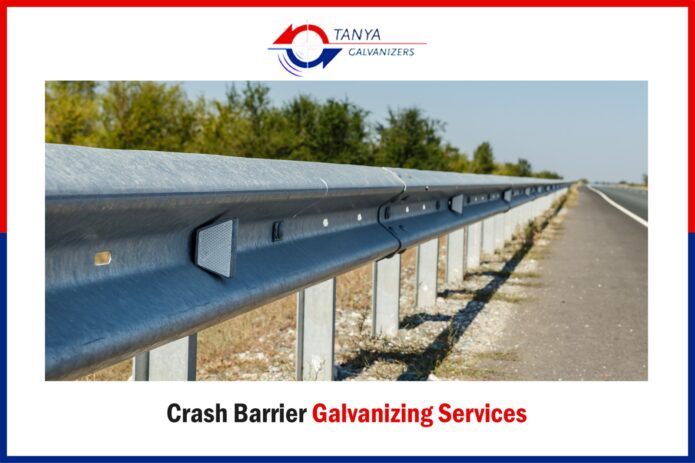

Why Galvanizing is a Must for Crash Barriers?

Crash barriers are exposed to various environmental conditions, including rain, sunlight, pollution, and coastal humidity. Over time, they may rust or weaken if not protected.

This is where galvanizing comes in.

Galvanizing is the process of coating steel with zinc, protecting it from corrosion and extending its lifespan. Tanya Galvanizers offers hot dip galvanizing services that:

- Provide rust protection for up to 50 years

- Offer a uniform and durable zinc coating

- Follow IS 2062, IS 10748, and other standards

- Require minimal maintenance

Choosing the Right Crash Barrier Manufacturers: What to Look For

When evaluating manufacturers, consider:

- Experience & Certifications: Choose a company that complies with MORTH specifications and IRC standards.

- Material Quality: Look for IS-grade steel and precision manufacturing.

- Galvanizing Capability: Ensure the company offers in-house galvanizing or partners with trusted galvanizers.

- Past Projects & Client Testimonials: Proven performance is key.

- Delivery and Support: Timely supply and after-sales support reflect reliability.

Tanya Galvanizers: Trusted Partner in Crash Barrier Galvanizing

Tanya Galvanizers is recognized for its expertise in crash barrier galvanizing. With over two decades of experience, they offer high-quality zinc-coated crash barriers that meet both Indian and international safety standards.

Their state-of-the-art plant in Gujarat serves as a key supplier to leading infrastructure companies across the country. If you are looking for dependable crash barrier manufacturers or galvanizing services, Tanya Galvanizers delivers both quality and trust.

Do you need robust and long-lasting crash barriers for your next project?

Contact Tanya Galvanizers today for high-quality galvanized crash barriers that comply with national safety standards and deliver unmatched performance.

Frequently Asked Questions

-

What is the purpose of crash barriers?

Crash barriers prevent vehicles from colliding with hazardous obstacles or falling off the road. They absorb impact and reduce the severity of crashes.

-

Why is galvanizing necessary for crash barriers?

Galvanizing protects crash barriers from rust and environmental damage, ensuring a long life and consistent safety performance.

-

How long do galvanized crash barriers last?

With proper galvanization, crash barriers can last 25–50 years, depending on exposure conditions and maintenance.

-

How can I ensure I’m buying from a trusted crash barrier manufacturer?

Look for certifications, compliance with MORTH & IRC standards, and proven project history.