Galvanization is considered to be a significant process which involves the process of applying a layer of zinc i.e. zinc coat over steel or iron in order to prevent them from rusting and extending their life for long. To undergo this process, one can find several companies offering the service but out of all, the best and well-known company that you can resort to is Tanya Galvanizers. It is known to serve its clientele with a detailed process followed with rendering a perfect service – a solution for long!

For these processes, there are crash barriers supplied by Tanya Galvanizers – one of the premium crash barrier manufacturers! Now what is a crash barrier? Crash barriers are traffic barriers also know as Armco barriers that are basically designed to protect the vehicles from colliding with dangerous barriers like boulders, walls, large storm drains or buildings. These crash barriers can also be placed at the roadside to avoid errant vehicles going through steep slopes or also from entering deep waters.

The aim of supplying these galvanized crash barriers is to reduce the collision and this is the reason why they are mostly placed within medians of divided highways as a large number of accidents occurs here. With these crash barriers, it becomes possible to prevent the unorganized or wayward vehicles from entering through the wrong side. There are certain places that should always be shielded with these crash barriers for assuring safety of the people. To name a few places, vulnerable areas like school yards, pedestrian zones and fuel tanks must be guarded with these crash barriers.

Tanya Galvanizers understand the significance of the crash barriers and make sure to provide the best one that can enable a full proof secured solution in case of emergencies. With continued service to many clients, it has attained a title of one of the best galvanized crash barriers suppliers across the India. These crash barriers by Tanya Galvanizers are normally placed at drainage crossings, near large signs or illumination poles, near steep slopes and even at the bridge ends – the places that may pose a danger and unforeseen accidents.

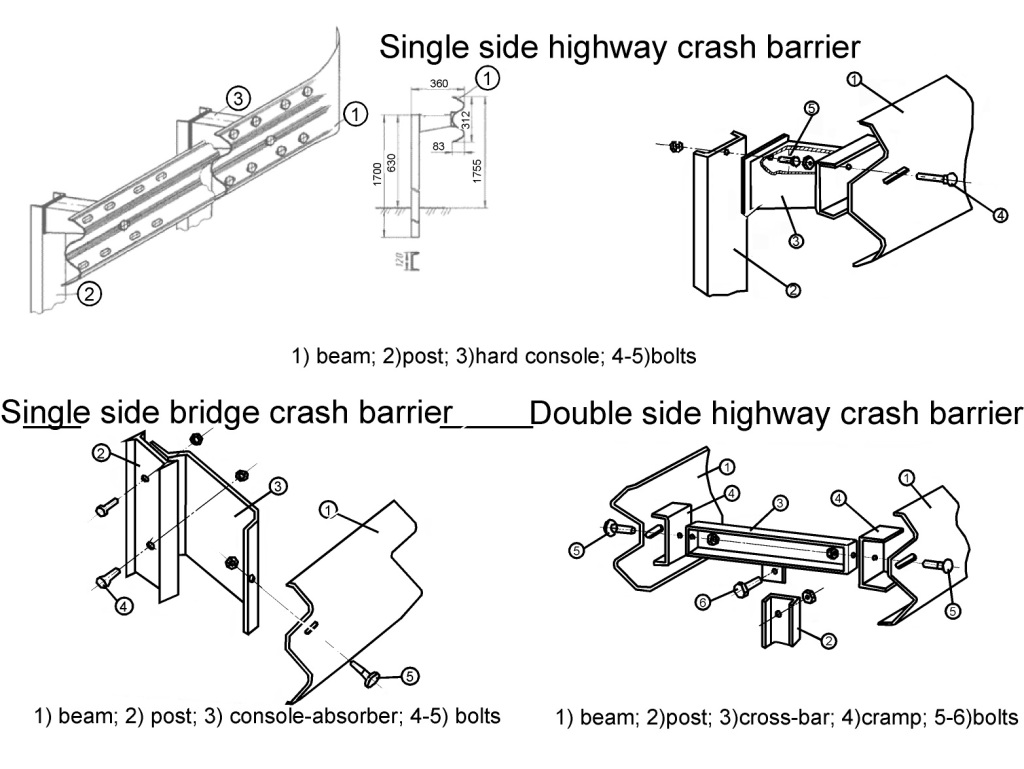

Tanya Galvanizers provide four types of crash barriers that can be used as per the respective requirements of the clients:

- Roadside barriers

- Median barriers

- Bridge barriers

- Work zone barriers

Having the characteristics of being flexible, semi-rigid or rigid, Tanya Galvanizers provides the same depending on the requirement and where it needs to be installed. It is advisable to consider the place of installation before deciding its type so that it can act and justify as the best safeguarding material for all the travelling motorists.

So if you are in search of one such company who provides end-to-end secured solution, resort to the best of all – Tanya Galvanizers and safeguard the respective places with required safety measures. For more information visit: http://www.galvanizers.co.in/crash-barrier.html