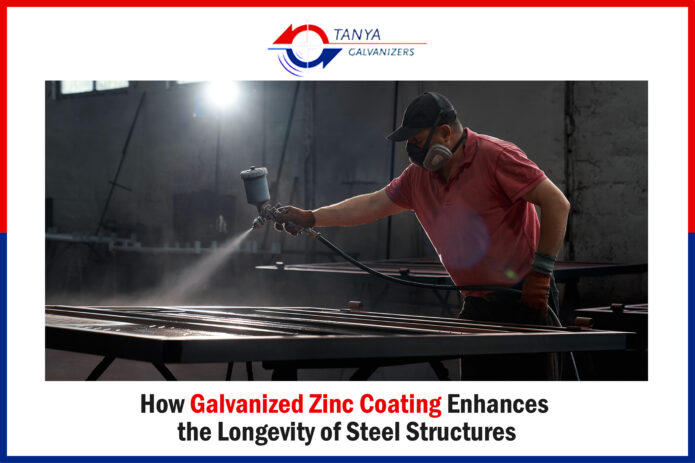

Steel is a vital material in construction and industrial applications, prized for its strength and versatility. However, steel’s susceptibility to corrosion poses a significant challenge. This is where galvanized zinc coating comes into play as an essential solution to enhance the durability and longevity of steel structures. Applying a protective zinc layer ensures that steel withstands harsh environmental conditions, extending its life and minimizing maintenance costs.

What is Galvanized Zinc Coating?

Galvanized zinc coating is the process of applying a layer of zinc to steel or iron surfaces through techniques such as hot-dip galvanizing or electro-galvanizing. As more reactive than steel, zinc acts as a sacrificial layer, protecting the base material from corrosion. When exposed to moisture and oxygen, zinc forms a stable zinc oxide layer, which further reacts with carbon dioxide to create zinc carbonate. This natural barrier shields the steel from oxidation, ensuring structural integrity.

The Science Behind Galvanized Zinc Coating

The effectiveness of zinc coating lies in its ability to provide both physical and electrochemical protection:

- Barrier Protection:

The zinc layer acts as a physical barrier, preventing moisture and oxygen from contacting the steel surface. This reduces the chances of rust formation. - Cathodic Protection:

Even if the zinc coating gets scratched or damaged, it protects the exposed steel through cathodic action. Zinc is more electrochemically reactive than steel, meaning it corrodes first, sparing the steel beneath. - Self-Healing Properties:

Galvanized zinc coatings have self-healing abilities at small scratches or abrasions. The zinc ions migrate to damaged areas, filling gaps and preventing further corrosion.

Advantages of Galvanized Zinc Coating

Galvanized zinc coating offers several benefits, making it a preferred choice for protecting steel structures:

- Long-Lasting Protection:

Galvanized steel can last for decades, even in harsh environments such as coastal regions or industrial zones with high humidity and pollution. - Low Maintenance:

Structures with galvanized zinc coatings require minimal upkeep, significantly reducing maintenance costs. - Cost-Effective Solution:

While the initial investment in galvanizing may be higher than traditional painting, the long-term savings in maintenance and replacements make it a cost-effective choice. - Eco-Friendly:

Zinc is a recyclable material, and galvanized steel can be reused, contributing to sustainability efforts in construction and manufacturing.

Applications of Galvanized Zinc Coating

The versatility of galvanized zinc coating makes it suitable for various applications across industries:

- Construction:

Galvanized steel is used in building frameworks, roofing, and reinforcement bars to ensure structural durability. - Automotive:

Components like car frames and chassis are coated with zinc to withstand road conditions and prevent rust. - Agriculture:

Galvanized steel is extensively used in irrigation systems, fencing, and silos to resist the corrosive effects of water and chemicals. - Infrastructure:

Bridges, highways, and railway tracks rely on galvanized steel for long-lasting performance under extreme weather conditions.

How Zinc Coating Enhances Steel Structures

- Protection Against Corrosion:

The primary benefit of zinc coating is its ability to prevent rust and corrosion, even in the most aggressive environments. - Enhanced Aesthetic Appeal:

Zinc coatings provide a smooth and shiny finish, which adds to the aesthetic appeal of steel structures. - Improved Structural Strength:

By protecting steel from corrosion, galvanized zinc coatings maintain the structural strength of steel components over time. - Longevity in Extreme Conditions:

Whether in coastal regions with high salt content or industrial settings with chemical exposure, galvanized zinc coatings ensure the longevity of steel structures.

Why Choose Galvanized Zinc Coating for Your Projects?

Investing in galvanized zinc coating is a smart choice for any project that demands long-lasting and reliable steel performance. Whether you’re building a residential structure, an industrial plant, or infrastructure like bridges and highways, galvanized steel offers unparalleled protection and cost efficiency.

Conclusion

Galvanized zinc coating is an indispensable technology for enhancing the durability and longevity of steel structures. Its ability to protect against corrosion, maintain structural integrity, and reduce maintenance costs makes it a preferred choice across industries. By investing in galvanized zinc coatings, you not only ensure the safety and reliability of your projects but also contribute to sustainability and long-term cost savings.

Connect with Tanya Galvanizers today if you’re looking for trusted galvanized zinc coating solutions. Our expertise in galvanizing services guarantees high-quality protection for your steel structures, ensuring they stand the test of time. Contact us now to discuss your project needs!