Powder coating on hot dip, as can be understood from the name, is a procedure to apply a coating of a special powder on steel that is hot dip galvanized. This particular coating of powder applied on the hot dip galvanizing process provides a significant amount of flexibility as well as a long life. It is precisely the reason as to why powder coating on hot dip galvanized steek has become so popular in recent times. Now, there are three of the major problems that are usually associated with the powder coating on hot dip galvanizing.

- Pin holing of the coating – It is caused by the formation of small air bubbles in the coating at the time of curing or stoving cycle. These bubbles give rise to small craters, and are unsightly. At the same time, it reduces the life and durability of the product.

- Poor adhesion – In the final step of hot dip galvanizing process, water quenching is involved usually in a weak dichromate solution. If it is not done appropriately, the adhesion of the powder coating tends to be quite poor, and hence ineffective.

- Incomplete curing – The powder coatings are thermosetting resins that cross link to their ultimate organic form when they are maintained at a temperature of 180 degrees Celsius for approximately ten minutes. The curing overs are designed to do the task efficiently. But if the curing is incomplete, the coating would not be perfect.

Read more: Hot Dip Galvanized Steel

To get rid of these problems, it is of immense importance to follow a few of the most essential tips in this regard for perfect powder coating on hot dip galvanized steel.

- Carry out the hot dip galvanizing process but do not chromate or water quench

- All the drainage spikes as well as the surface defects should be mandatorily removed

- Powder coating should be done within a maximum of twelve hours after galvanization

- Precautions need to be taken to make sure that the surfaces do not get wet, and ensure that the item is not left outside

- It is essential to keep the surface clean without any kind of contamination before the application coating

- In case any contamination, the surface should be necessarily cleaned with compatible detergent or solvent before the application of powder coating

- It is ideal to pre treat the hot dip galvanized steel with zinc phosphate to make sure that the highest adhesion is obtained, and most importantly the surface should be perfectly clean before the treatment

- Before the application of powder coating, the work should be pre heated

- Finally, it is to be made sure that curing is perfect and the correct curing should be checked by solvent testing

Keeping all these tips in mind would make sure that the intended results are obtained. So, at any point of time, you are search of the best hot dip galvanizing services in Vadodara, Prashant Galvanizers would undoubtedly be the best option. We are a leading hot dip galvanizing service provider to make sure to provide the users with premium quality services. Moreover, it is recommended to choose a trusted, reputed, and reliable service provider like Prashant Galvanizers if you wish to get the best solutions in this regard.

For more information on hot dip galvanizing by Galvanizers, click the link:

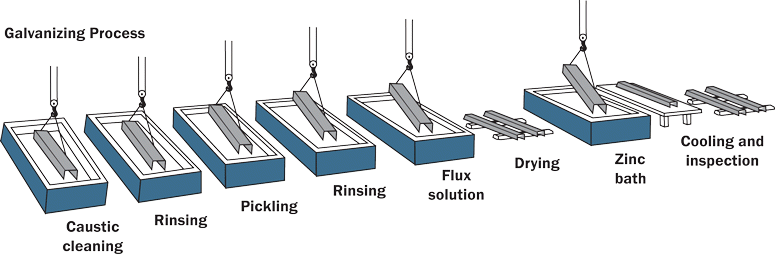

There is a general misunderstanding among common people that every zinc coating is called galvanization but this is not true as there might be many processes through which a zing coating can be applied. Hot Dip Galvanizing is a coating which is formed after immersing a steelwork in molten zinc. There are however two different processes of hot-dip galvanizing which are pregalvanizing and batch galvanizing.

There is a general misunderstanding among common people that every zinc coating is called galvanization but this is not true as there might be many processes through which a zing coating can be applied. Hot Dip Galvanizing is a coating which is formed after immersing a steelwork in molten zinc. There are however two different processes of hot-dip galvanizing which are pregalvanizing and batch galvanizing.